This section contains all the blog content, which is primarily focused on documenting the build. For design information, see the articles contained under the categories in the navigation bar.

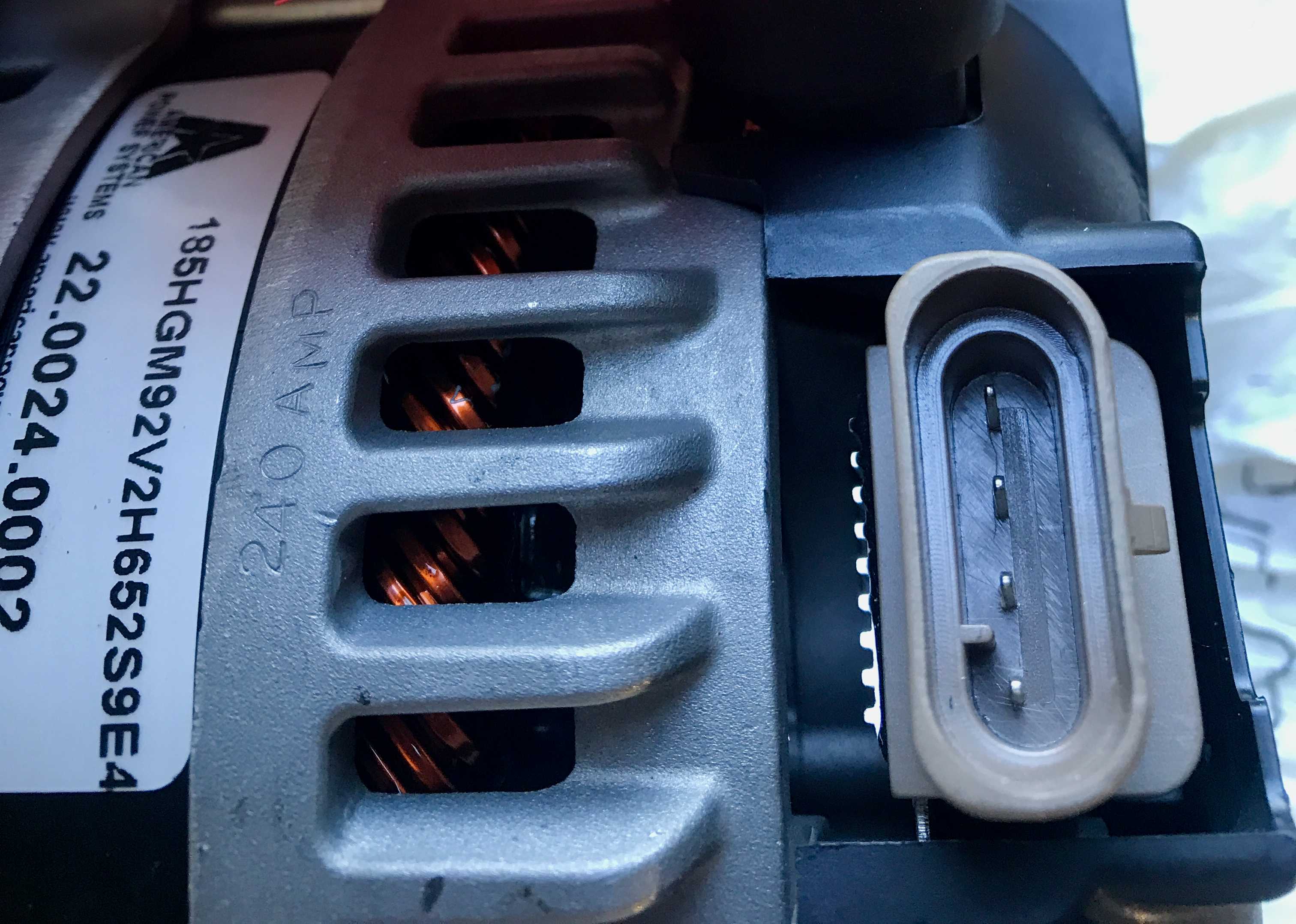

24V Alternator Testing

The APS alternator performs pretty close to advertised performance but requires driving or higher than nominal idle to supply power. If you are looking for serious charge capability we'd recommend this product.

Roof Rack Installation

We installed a 137-inch roof rack and 800 watts of solar panels on Van 2.0. The rack is composed of angle aluminum, 15 series 8020, and Hein's roof rack mounts.

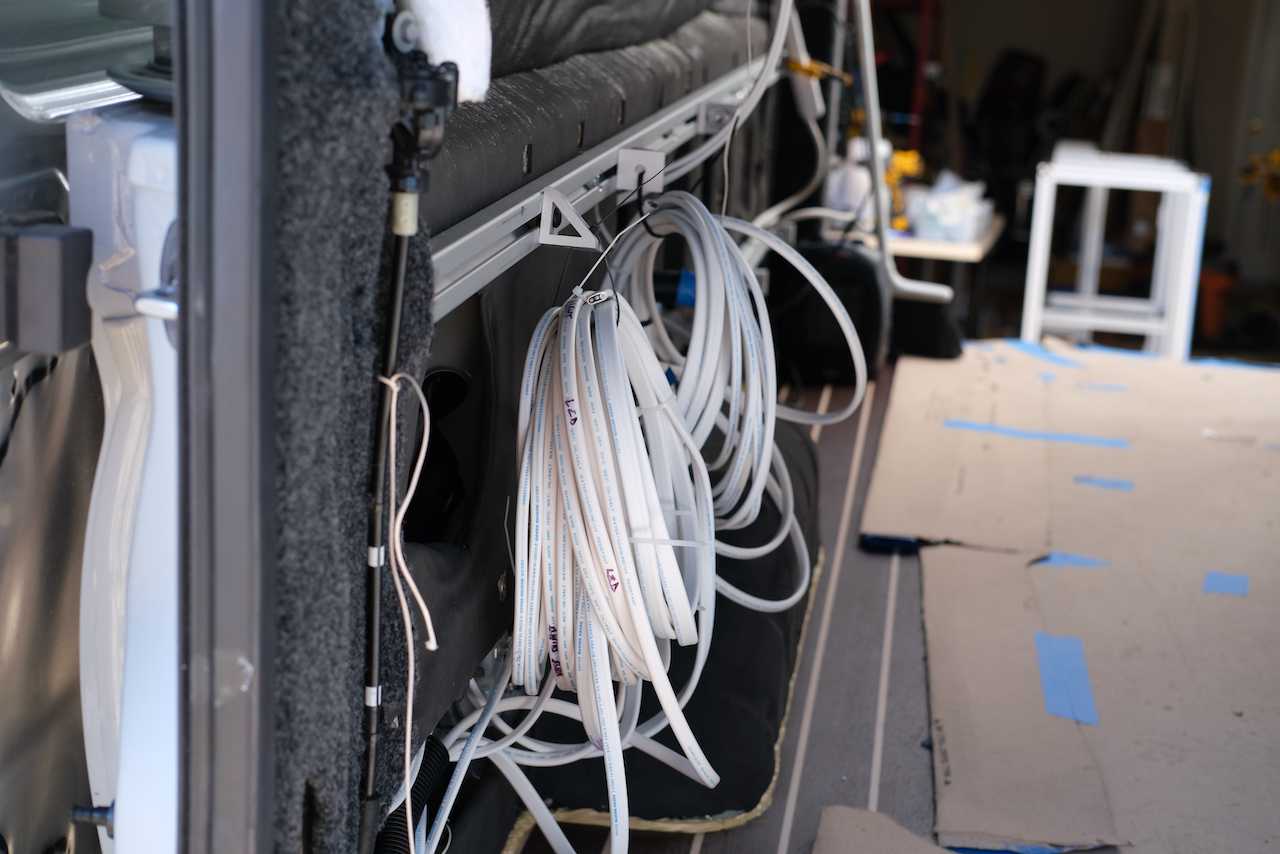

Wire Runs

We measured, planned, and ran all of our branch circuit wiring. We also ran conduit for future expansion.

Mudflaps and Wheel Well Liners

We installed WeatherTech rear mudflaps and OMAC rear wheel well liners.

Wall and Ceiling Insulation

We used automotive felt, neoprene, and thinsulate for thermal (and some acoustic) insulation of the walls and ceiling.

Structural Design and Mockup

Van 2.0 was built using 15 series 8020 extruded aluminum for its precision, strength, and popularity among DIY van conversion projects. To ensure accuracy, the design process included creating a 3D model in SketchUp and a full-size wooden mockup. If starting over, the we would use the 1515-ULS profile for weight savings.

Internal Arrangement

Van 2.0 features a fixed raised bed with substantial garage storage underneath, a split driver and passenger side galley with center aisle, a booth seat to support dining for three, and loads of soft overhead storage.

Battery Interconnect Electroplating Trials

We are electroplating our battery interconnects with Nickel to provide corrosion resistance. Our first attempt/protocol failed but we learned some valuable lessons.

Battery Interconnect Fabrication Trials

We performed some fabrication trials of our series and parallel interconnects. We concluded that portions of the design were not able to fabricated. Based on these lessons we planned another design iteration.

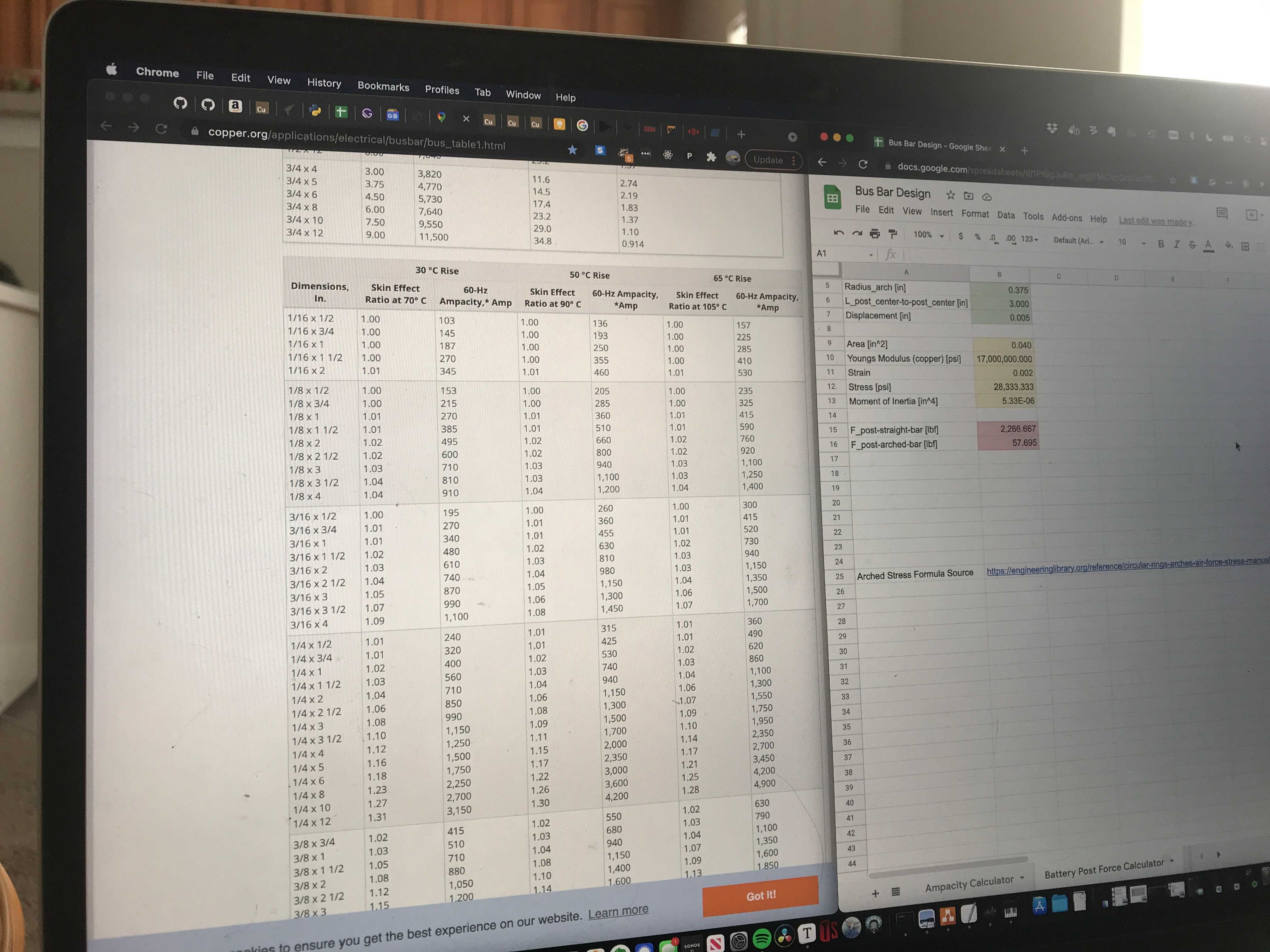

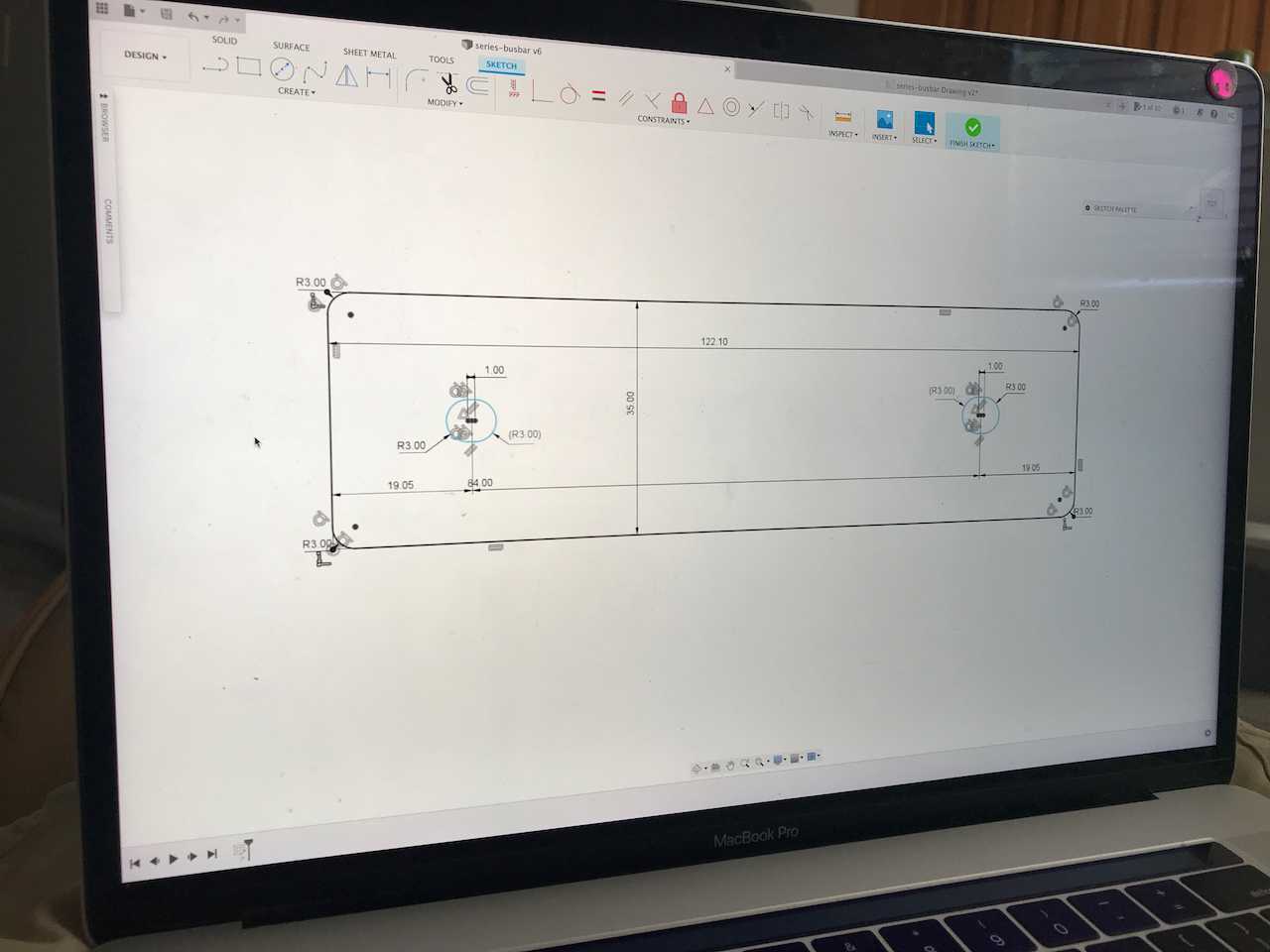

Battery Interconnect Design

We designed the parallel and series interconnects that join the individual cells to form our battery. We ordered material to perform some fabrication trials.

REC Q CAN Comms Voltage Sense Anomaly

We discovered an anomaly with BMS cell voltage measurements during benchtop testing. With the help of REC we found it was an issue with our battery simulator, which we resolved.

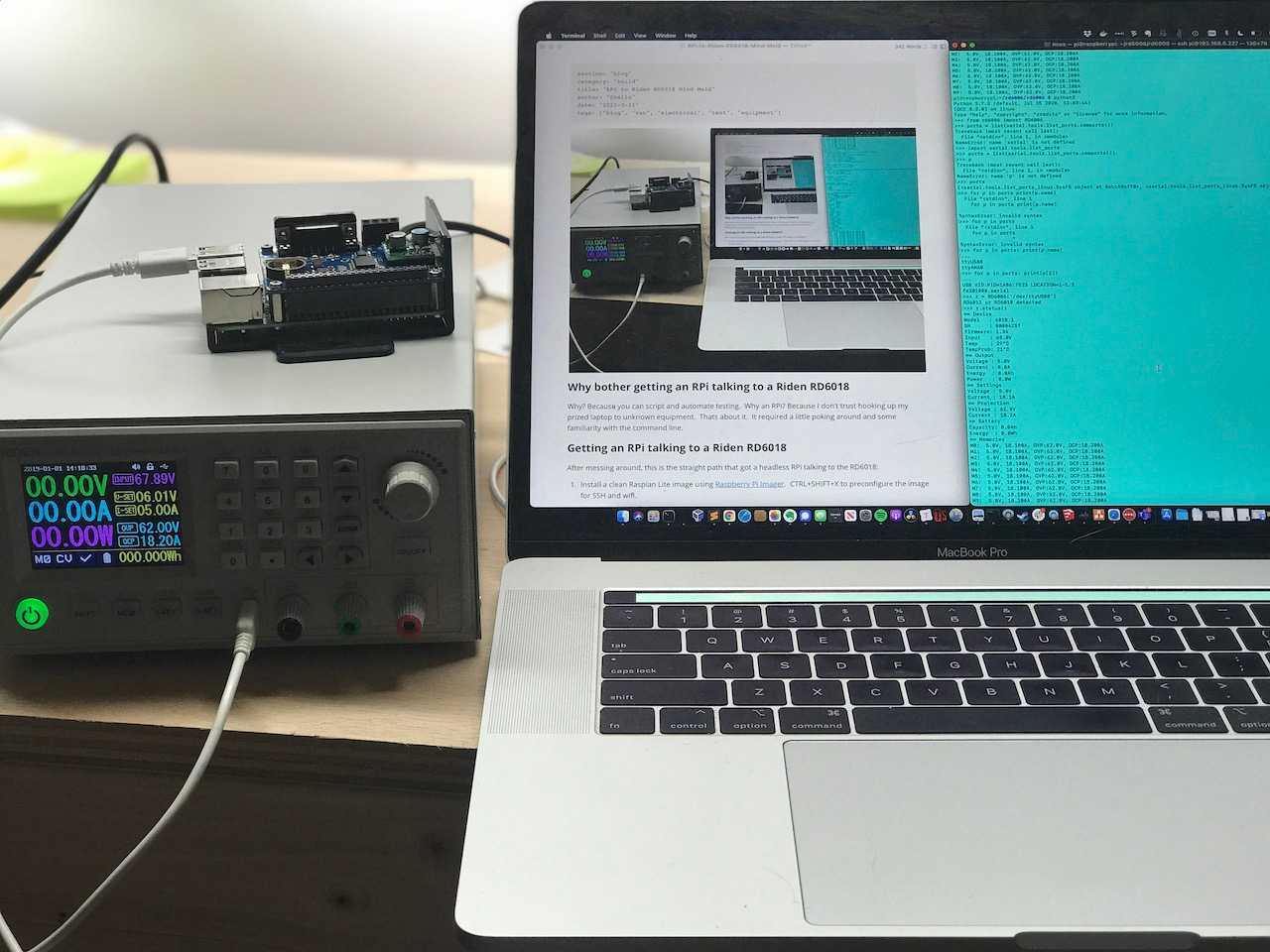

RPi to Riden RD6018 Comms

We setup an RPi to communicate with and control to our Riden RD6018. This will allow us to script and automate testing of van electrical components down the road.

Battery Management System Failure?

While driving the Going-to-the-Sun road in Glacier National Park, we had a complete electrical system failure.

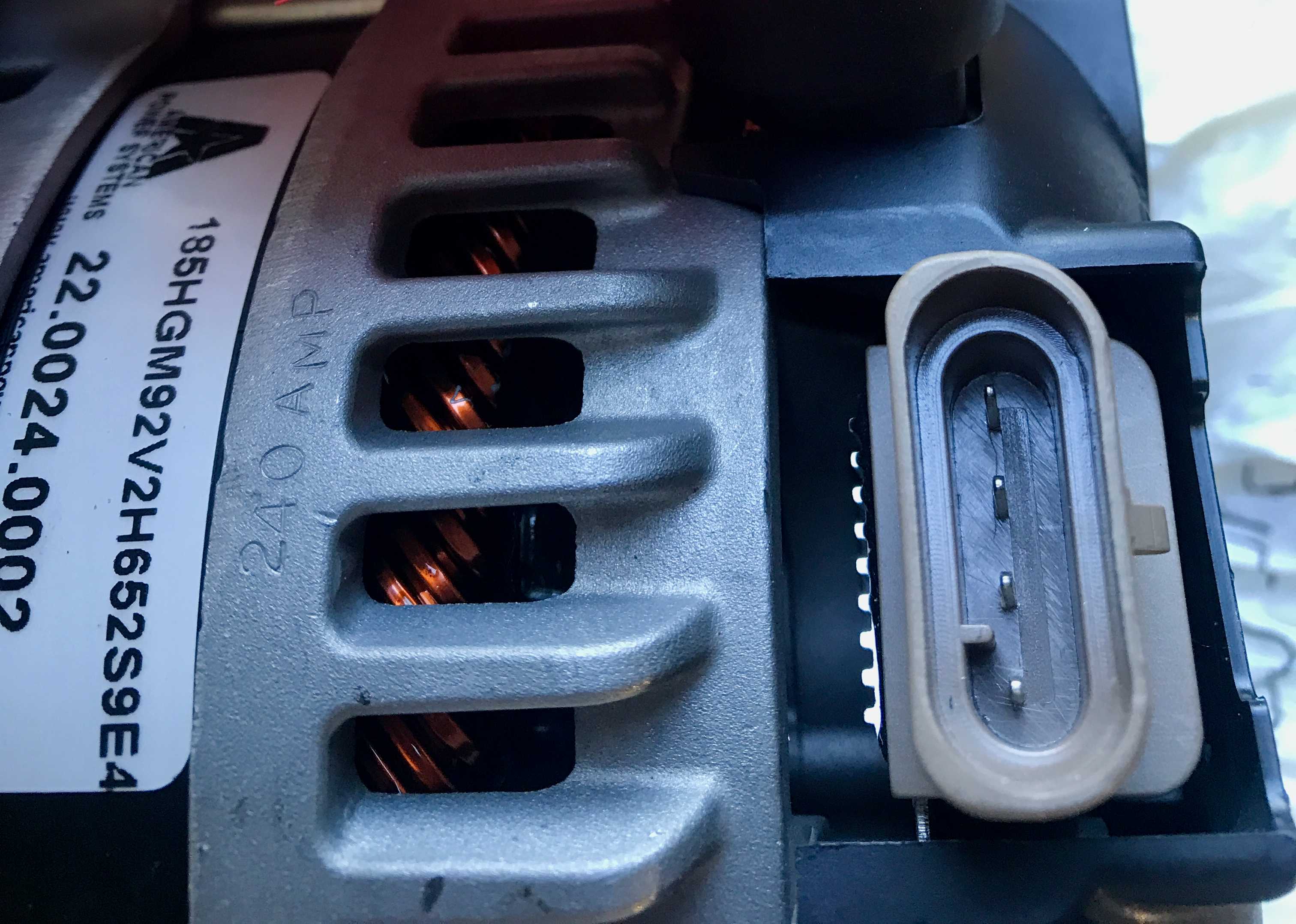

24V Alternator Install

We installed a dedicated 180A 24V alternator to charge our battery. The alternator install was a bit of a challenge due to the tolerancing of the bracket and the incorrect length of the supplied belt.

SmartPlug/Aux Solar/Exterior Plug

We designed, had fabricated, and installed some custom panels for our shore power, aux solar, and exterior outlets. We highly recommend this approach.

8020 Assembly and Install

We built Van 2.0's structure with 15 series 8020 extruded aluminum based on its precision, strength, and popularity among DIY van conversion projects. Ordering cut-to-length and counter-bored pieces made assembly and install a breeze.

Seat Covers

We installed seat covers because we have cats and commonly drive while wearing wet wetsuits. Also, they match our interior color scheme.

Harness Reroute

We rerouted the factory harness in the cargo area. For our build, it made sense. YMMV.

Plusnuts

We used a pneumatic tool to install 1/4-20 plusnuts in about every compatible factory hole. In hindsight we would have used the star-lock-washer approach to improve spin-out resistance.

Floor Install

Our floor is an seamless, water proof, edge sealed layer composed of lonseal, 1/2" baltic birch, and minicell foam.

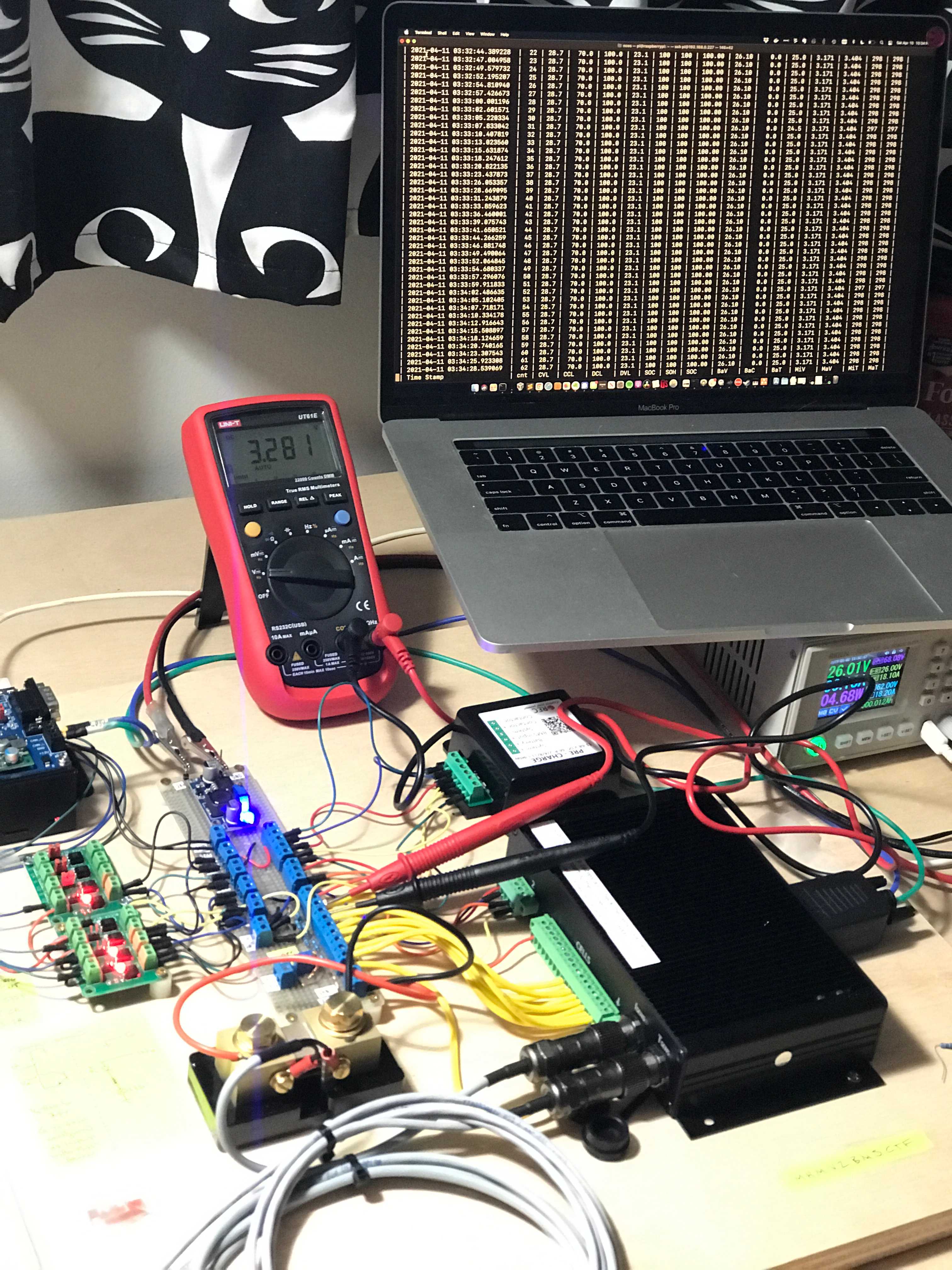

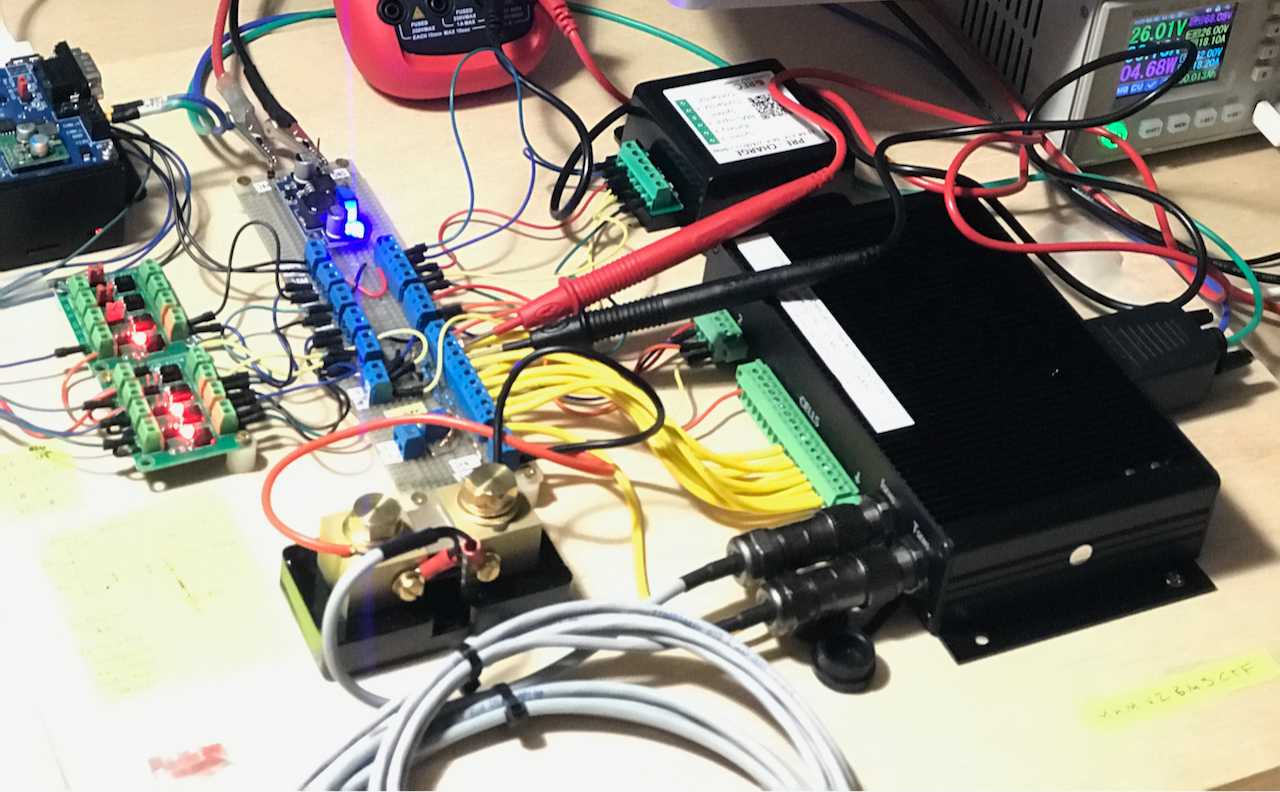

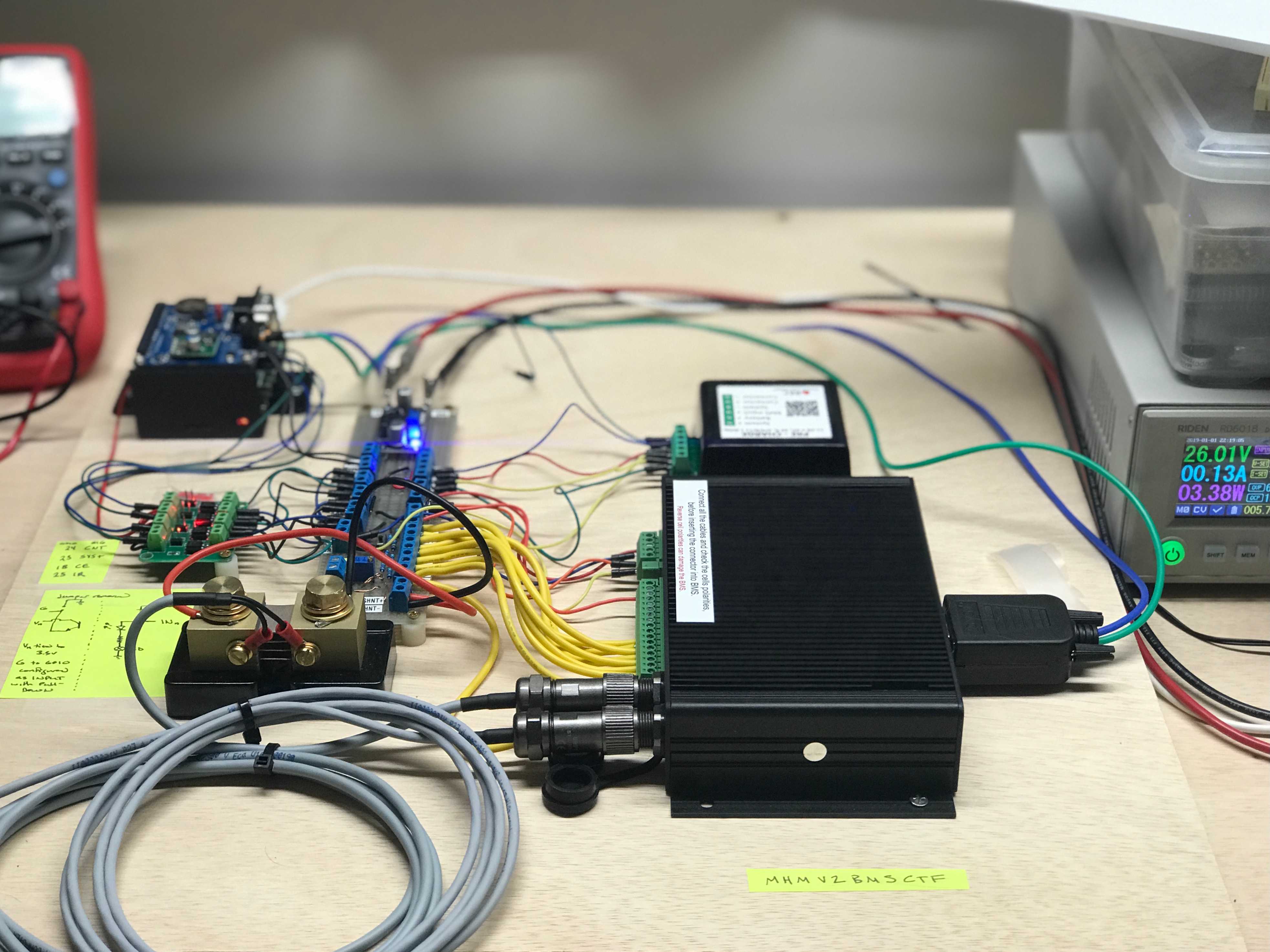

REC BMS Testing

We tested and captured data to prove out and characterize the REC BMS protection and operation. This was based on our previous work to get an RPi to communicate with our Riden power supply, our digital multimeter, and the BMS.

Battery Interconnect Fabrication

We successfully completed the fabrication of our battery interconnects.

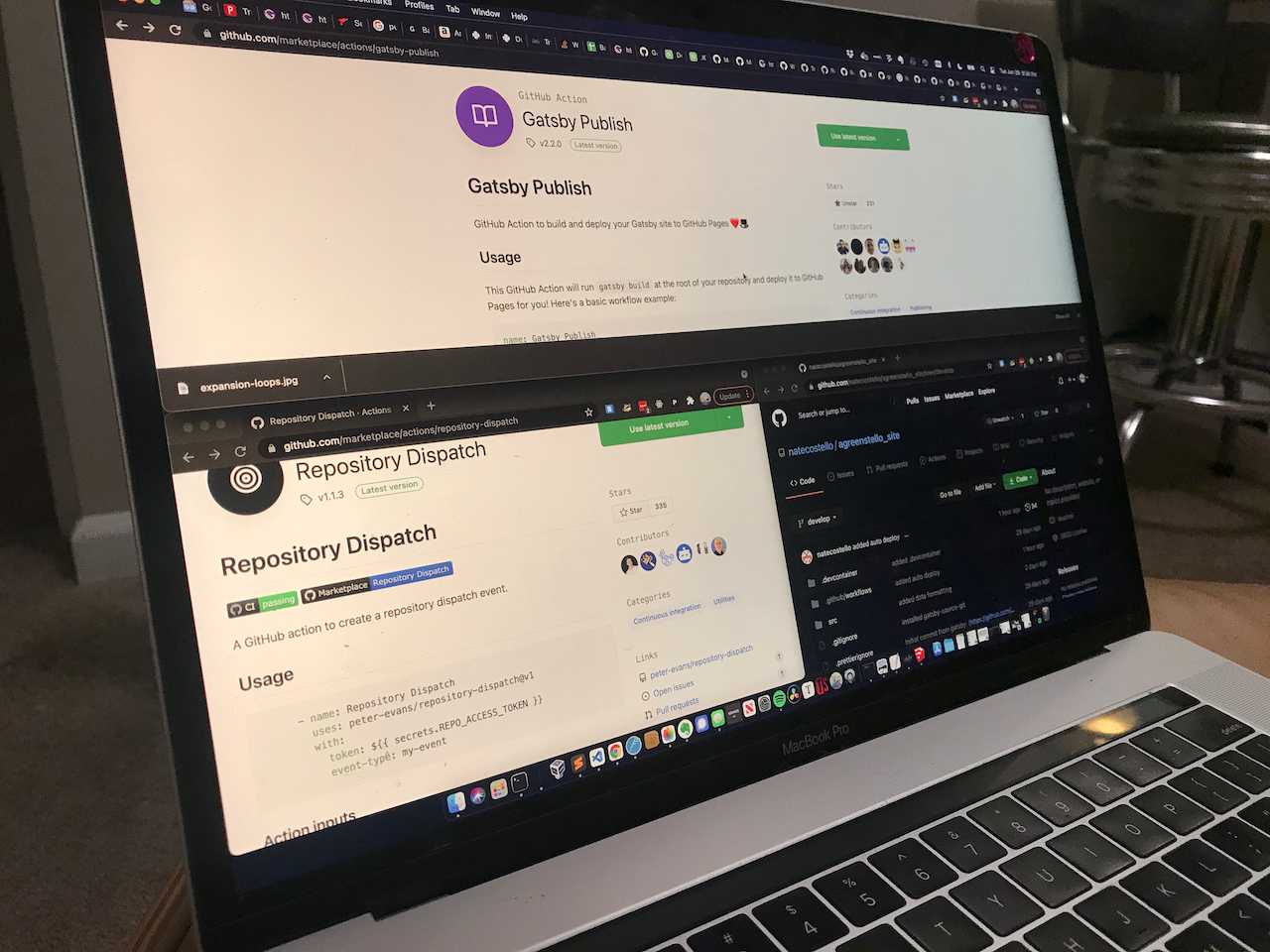

Web Page Dev Ops

We are using Gatsby, a static site generator, for this website. It uses a GitHub repository of markdown files for all the content, and turns that into HTML automatically.

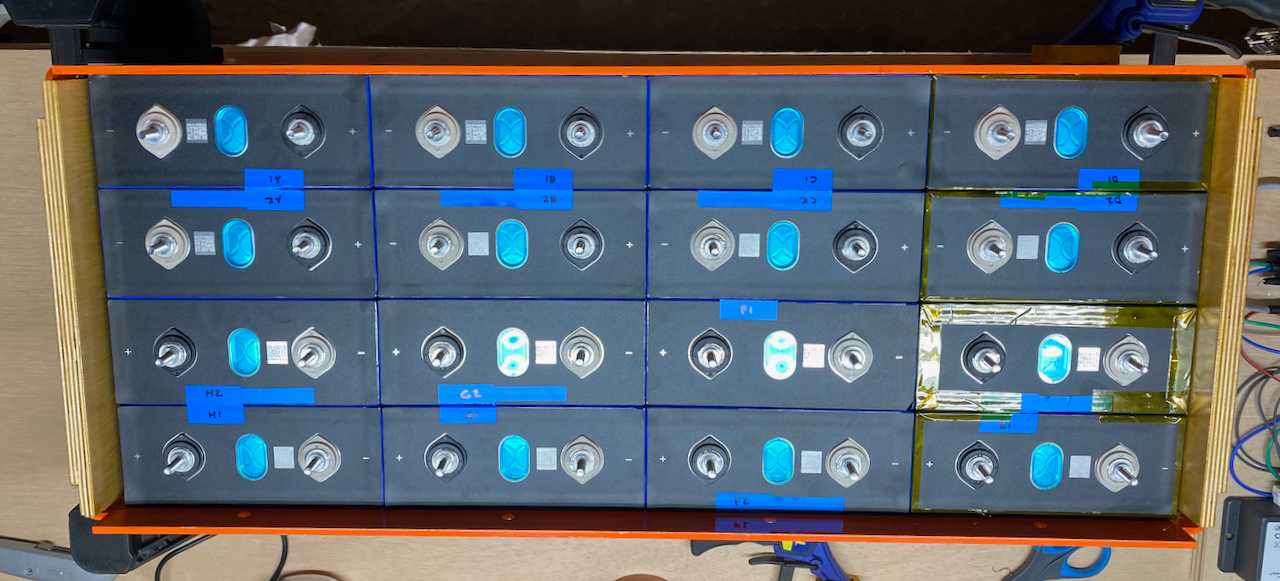

Battery Assembly Dry-fit

We assembled our LFP cells and other components to ensure everything fit up properly. We verified our battery design was physically sound.

RPi to REC Q CAN Comms

We setup an RPi to communicate over CAN with our REC Q BMS. This will allow us to log BMS parameters during electrical system testing.It will also lay the ground work for interfacing our homebrew electrical monitoring and control functions with the BMS.

Van 2.0 Order

We ordered an extended length, high roof, AWD 2021 Ford Transit Cargo Van.

Starlink

After using Starlink "on-label" seven months, we modified it for DC power and flat roof mounting. For full-timers that work out of a van or RV, Starlink is a game changer.

Wall Panel Fab and Install

We designed and installed wall panels, made from expanded PVC sheet and upholstered with neoprene and marine vinyl. These panels are supported by and fastened to custom brackets, stiffening panels, and L-track.

Overhead Storage

We modified dufflebags with grommets and stiffeners to form our overhead storage. Think Mule bags without the expense. It's light, cheap, and soft

L-Track Installation

We installed 6 lengths of L-track. These runs form part of the structure to support ceiling panels, wall panels lights, over-head storage, and provide general L-track utility.

Wall 8020 Installation

We installed lengths of 1575 series 8020 down the lower sides of the van walls to facilitate future attachment of all of our 8020 structure.

MaxxFan Install

We installed a single MaxxFan in the rear-most possible location.

Battery Interconnect Electroplating Trials Part II

We are electroplating our battery interconnects with Nickel to provide corrosion resistance. We upgraded our rig based on the lessons from our first failure. We upgraded our protocol based on some advice from a chemically inclined friend. The latter got us an acceptable result.

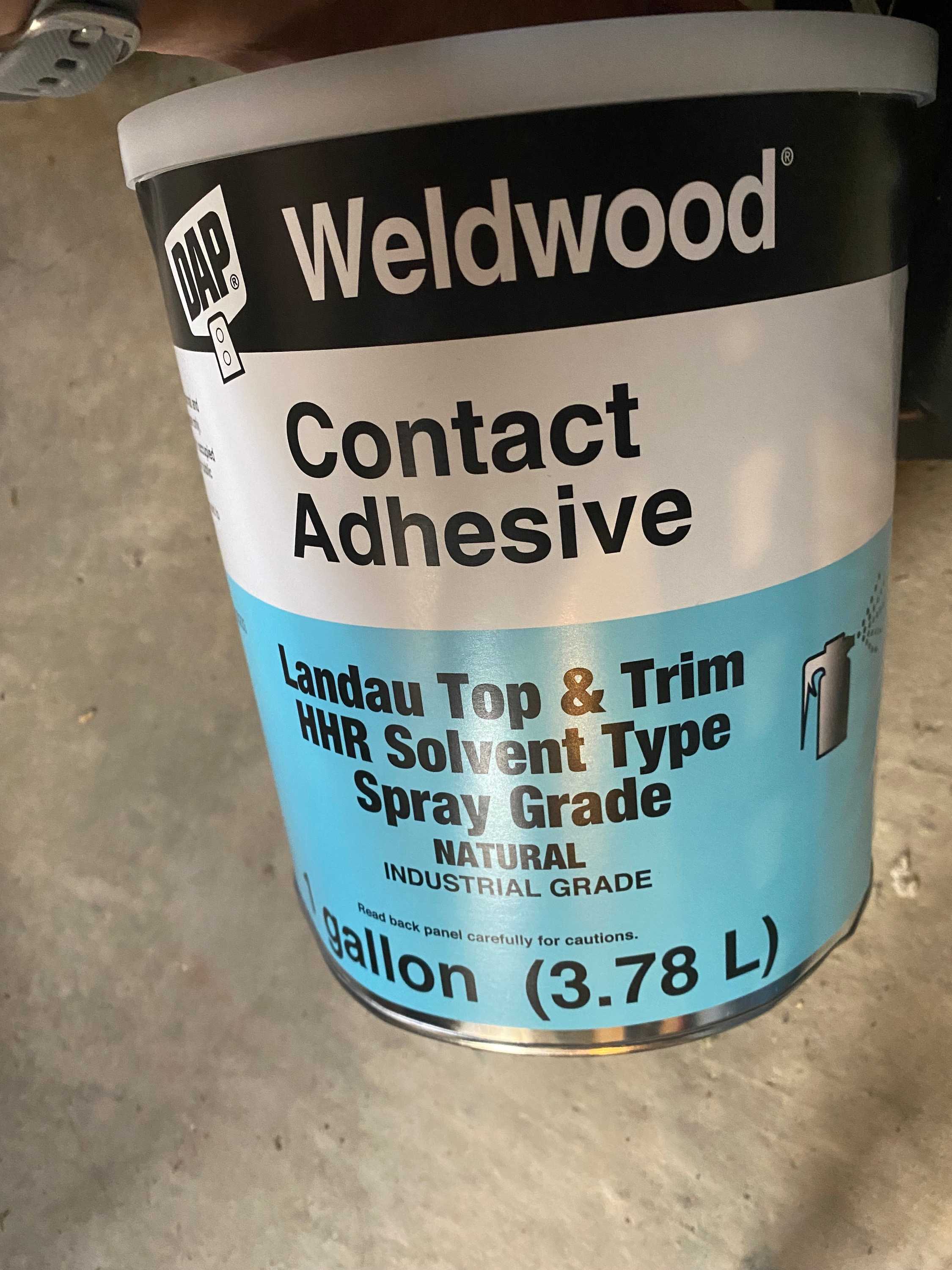

Adhesive Test for Inner Walls

Weldwood Landau Top and Trim contact adhesive can be used to successfully stick neoprene to CoreRigid corrugated ABS panels. This means we have identified a suitable alternative to plywood for our interior wall panels.

Battery Interconnect Design V2

Based on our fabrication trials, we redesigned the parallel and series interconnects that join the individual cells to form our battery. The fabrication required for our new design is covered by what we proved in the trials. We ordered production material.

Unboxing the Refrigerator and Freezer

This is Sophia's first post. It describes our unboxing... which is very great and interesting.

LFP Cell Unboxing

We unboxed and took physical measurements on our LFP cells that will form our battery.

RPi to UNI-T UT61E Comms

We setup an RPi to communicate with log from our UNI-T UT61E. This will allow us to script and automate testing of van electrical components down the road.